Industrial vacuum cleaners are high-powered and designed specifically to work in high demand spaces, such as construction zones and manufacturing facilities. Read More…

As a leader in the vacuum cleaner manufacturing industry, Multi-Vac offers vacuums for a variety of applications. Products include central industrial vacuums, portable vacuum cleaners and more.

Delfin Industrial Vacuums is an innovative leader in the vacuum cleaners industry. We focus on continually improving our products and our services, so you are only ever getting the best from us. Our team is dedicated to finding the right industrial vacuum system for your company’s specific needs. Delfin is an ISO 9001 certified company. We offer our customers unrivaled customer service and...

We aim to achieve measurable cost savings for you while producing a cleaner and safer work environment in your workplace. We meet your needs for cleaning or maintaining, recycling, non-destructively excavating, or improving air quality.

At Mark C. Pope Associates, we take pride in offering advanced vacuum cleaning solutions tailored to meet the rigorous demands of industrial and commercial environments. With decades of experience in the field, we have built a reputation for delivering high-performance vacuum systems that stand up to heavy-duty use while ensuring efficiency, safety, and cleanliness in every application.

More Vacuum Cleaner Manufacturers

Applications

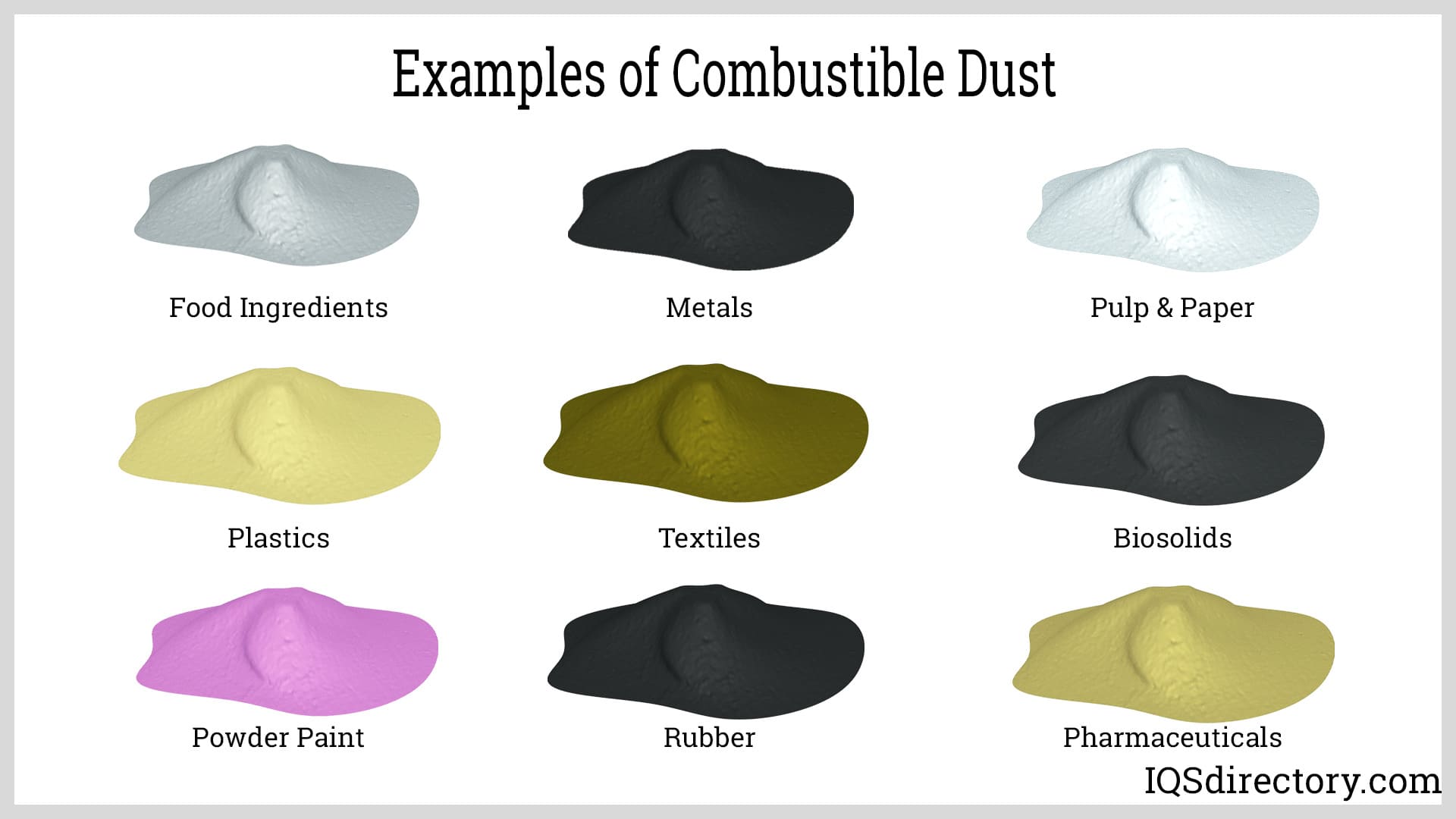

Industrial vacuum cleaners are essential industrial cleaning equipment for custodians, facility maintenance workers, carpenters, and a variety of tradespeople committed to maintaining pristine workspaces and minimizing airborne dust, hazardous particulates, and industrial debris. In demanding environments such as factories, warehouses, production floors, workshops, and construction sites—where dust, shavings, and contaminants are prevalent—an industrial vacuum is often the only effective solution for ensuring superior indoor air quality, occupational safety, and regulatory compliance. These machines play a key role in dust management, OSHA compliance, and the prevention of workplace accidents caused by combustible dust or hazardous spills.

Modern industrial vacuum cleaners are engineered to manage a diverse array of materials commonly found in industrial, commercial, and specialized environments. They efficiently extract and contain substances like toxic media, coolant, oil mist, fine powders, debris from machine grinders, metalworking chips and fluids, abrasives, welding and soldering fumes, and even non-free-flowing or potentially explosive particulates. Industrial vacuum systems with specialized filtration can also be used for asbestos abatement, silica dust collection, or pharmaceutical powder recovery. In some manufacturing applications, industrial vacuums are also employed to reclaim and recycle surplus materials—such as metal shavings, polymers, or valuable powders—that might otherwise be wasted, increasing material efficiency and reducing operational costs.

Industrial vacuum cleaning technology plays a vital role across a broad spectrum of industries, supporting both general housekeeping and specialized dust collection. Key sectors include woodworking (for sawdust and wood chips), metalworking (for metal dust and shavings), manufacturing, electronics production, pharmaceuticals, food processing, and building maintenance. Its significance extends into healthcare facilities, cleanrooms, pollution control, the ceramic industry, and hazardous waste management. In settings requiring stringent cleanliness—such as hospitals, clean rooms, laboratories, and semiconductor fabrication plants—HEPA or ULPA-filtered vacuum systems are necessary to meet contamination and hygiene requirements, as well as ISO 14644 standards.

- Are you searching for the best industrial vacuum cleaner for your specific industry?

- Need to compare vacuum solutions for hazardous dust collection?

- Wondering how industrial vacuums support workplace safety or productivity?

- What are the top industrial vacuum cleaner applications in your sector?

For commercial and institutional environments, industrial vacuums are critical in maintaining regulatory compliance with organizations like OSHA, EPA, and NFPA, especially regarding combustible dust management, hazardous waste cleanup, and air quality standards. They also help ensure compliance with state and local environmental regulations regarding dust emissions and pollutant control.

History

The evolution of the vacuum cleaner is a testament to human ingenuity in solving the age-old problem of dust and debris removal. In 1860, American inventor Daniel Hess introduced the first mechanical floor cleaner, the carpet sweeper. His device used bellows to generate suction and a rotating brush to dislodge dirt from carpets and floors. Despite its innovative approach, Hess’s sweeper never entered mass production.

The next major development arrived in 1869 with Ives W. McGaffey’s “Whirlwind,” which utilized a handheld belt-driven fan to create suction. While more effective than Hess’s version, McGaffey’s model was awkward and cumbersome, limiting its widespread adoption. The breakthrough came in 1876 when Melville R. Bissell created the “Grand Rapids” carpet sweeper, featuring rotating brushes linked to wheels. This design, easier to operate and more effective, led to the founding of the Bissell company—a name still synonymous with vacuum cleaning today. Notably, Queen Victoria of England became an early adopter, ordering several units for royal residences. In 1900, Corinne Dufour advanced the concept further, integrating electricity and sponge-covered rollers moistened with water for more efficient cleaning.

By 1898, John S. Thurman had developed the pneumatic floor cleaner, a gasoline-powered machine that blasted dust away rather than sucking it up—a critical step in cleaning technology. Building on this innovation, British engineer Hubert Cecil Booth introduced the modern vacuum cleaner in 1901. Booth’s machine, “Puffing Billy,” used an internal combustion engine and a piston pump to draw air through a cloth filter, capturing dust and dirt. The device was so large it required horse-drawn transport, with tubes fed through windows into buildings. Booth ultimately created an electrically powered version, which, while still large, could be installed permanently in large premises or used in a similar fashion as its predecessor.

In 1905, Walter Griffiths introduced a portable vacuum cleaner, making individual operation feasible. This model featured a flexible pipe—an innovation at the time—enhancing usability. A year later, James B. Kirby launched the “Domestic Cyclone,” which captured dirt in water rather than a filter. The next leap occurred in 1907, when James Murray Spangler, a janitor from Ohio, invented the first motorized portable vacuum. Lacking manufacturing resources, Spangler sold his design to William Henry Hoover in 1908. Hoover encased the components in steel, added hose attachments, and by 1926 introduced disposable bags and the first upright vacuum cleaner—innovations that set industry standards for decades to come.

With the rise of synthetic plastics, vacuum cleaner manufacturers found new ways to reduce costs and improve product durability. By 1930, the first plastic vacuum cleaner was available, making the technology more accessible. The end of the Great Depression brought increased affordability and diversity in vacuum models, offering varied sizes, power levels, filtration capabilities, and operational styles to meet a range of cleaning needs. As commercial cleaning demands grew, the need for industrial-grade vacuum cleaners led to more powerful motors, heavy-duty construction, and enhanced filtration systems.

In 1963, David Oreck transformed commercial cleaning with the creation of the first upright vacuum designed specifically for professional use. Oreck’s lightweight, powerful design enabled workers to efficiently clean large commercial spaces with less physical strain. Over subsequent decades, engineers have further improved industrial vacuums, enhancing efficiency, filtration, mobility, and ergonomics. The 21st century has witnessed the rise of robotic vacuums, such as the Roomba by iRobot (introduced in 2002), which uses advanced sensors and artificial intelligence to autonomously navigate and clean. While industrial robotic vacuum cleaners are still emerging, the trend toward automation, smart sensors, and intuitive, energy-efficient cleaning technology continues to shape the industry.

Today, the industrial vacuum cleaner market features a wide array of technologies, including wet/dry vacuums, explosion-proof vacuums, HEPA-filtered vacuums, and central vacuum systems designed for high-volume, continuous operation in challenging environments. These innovations are driven by increasing environmental regulations, greater awareness of occupational health, and the need for more efficient cleaning solutions in sectors from manufacturing to healthcare.

How It Works

At its core, a vacuum cleaner functions by creating a pressure differential. One or more fans generate a low-pressure zone inside the vacuum, causing surrounding air—carrying dust, debris, and particles—to rush in. The powerful airflow is directed through filters or cyclonic separators, which trap contaminants and allow clean air to exit. The strength of this suction is determined by the vacuum’s motor power, the design of its airflow pathway, and the efficiency of its filtration system.

Some advanced industrial vacuum cleaners incorporate multi-stage filtration, cyclonic separation, and HEPA or ULPA filters for hazardous dust and allergen removal. In explosion-proof models, additional safety features prevent ignition of combustible dust. Central vacuum systems, meanwhile, create a permanent suction infrastructure throughout entire facilities, with debris collected at a single remote location for easy disposal. Wet/dry industrial vacuums include special collection tanks and filtration designed to separate liquids from solids safely, making them ideal for areas prone to spills or mixed debris.

- How does a cyclonic vacuum cleaner differ from a traditional model?

- Which filtration technologies best suit environments with hazardous or combustible dust?

- Looking for an explanation of HEPA vs. ULPA filtration?

- What are the advantages of bagless versus bagged vacuum systems in industrial settings?

Automation is also increasingly common in industrial vacuum design. IoT-integrated vacuums can monitor filter status, pressure differentials, and maintenance needs in real-time, alerting facility managers to potential issues before they become critical. This predictive maintenance capability minimizes downtime and extends equipment lifespan.

Types

The range of industrial vacuum cleaners is vast, with each type designed to address specific cleaning challenges in commercial, industrial, or specialized environments. Below are some of the most common and high-performing options. When choosing an industrial or commercial vacuum cleaner, it’s important to match the machine type to your specific use case, facility layout, and regulatory requirements.

Continuous Duty Vacuum

True to their name, continuous duty vacuums are engineered for 24/7 operation with minimal interruption. These machines feature large-capacity collection enclosures, robust motors, and easy-to-replace filters, ensuring high uptime and efficient debris management. Applications include manufacturing lines, food processing plants, packaging facilities, and pharmaceutical cleanrooms, where uninterrupted cleaning is essential. Advanced models, such as HEPA vacuum cleaners, are critical for environments requiring the continuous removal of airborne contaminants, hazardous dust, and fine particulates to comply with health and safety regulations.

Auto Vacuum

Auto vacuums are highly versatile machines designed to handle both wet and dry materials. While commonly used for automotive detailing and interior cleaning, they also excel in industrial applications—such as managing spills, cleaning up after renovations, or handling mixed debris in manufacturing facilities. Their high-capacity tanks and powerful suction make them indispensable for commercial car washes, garages, auto body shops, and construction cleanup operations. For businesses seeking multipurpose cleaning solutions, auto vacuums offer a cost-effective way to maintain vehicles, workspaces, and equipment.

Central Vacuum System

A central vacuum system provides a permanent, high-powered cleaning solution for large buildings or industrial complexes. Piping installed throughout the premises enables users to connect vacuum hoses at multiple locations, with all debris conveyed to a remote central collection point. This setup enhances cleaning efficiency, reduces noise in workspaces, and simplifies maintenance. Central vacuum systems are popular in commercial buildings, hotels, hospitals, laboratories, and luxury residential properties seeking robust, low-maintenance cleaning infrastructure. They are also favored in facilities with strict hygiene standards or frequent cleaning cycles, such as food processing plants and pharmaceutical manufacturing.

Portable Vacuum

A portable vacuum offers unmatched mobility and adaptability, perfectly suited for environments with dynamic or unpredictable cleaning requirements. Portable industrial vacuums come in backpack, wheeled, and canister formats, with many featuring multi-stage filters or HEPA filtration to ensure superior air quality. Ideal for spot cleaning, construction sites, temporary setups, and areas lacking permanent vacuum infrastructure, these vacuums provide flexibility without sacrificing power or filtration capability. Many models also feature brush roll agitators, adjustable suction, and ergonomic designs for user comfort and efficiency.

Wet/Dry Vacuum

Wet/dry vacuums are designed to handle both liquid and solid messes, making them invaluable in environments where spills, leaks, or mixed debris are common. These machines are often used in manufacturing, automotive, maintenance, and even disaster recovery scenarios. Their dual-function design supports rapid cleanup, minimizes downtime, and enhances safety by preventing slip hazards or equipment damage caused by standing liquids.

For home or light commercial use, there is a wide variety of vacuum models tailored to specific surfaces, debris types, and user preferences. Below is an overview of the most popular options for residential cleaning:

Canister Vacuum Cleaner

Canister vacuum cleaners consist of a powerful motor and dust collection chamber housed in a movable canister, connected to a cleaning wand by a flexible hose. This design provides excellent maneuverability for cleaning under furniture, stairs, drapes, and hard-to-reach areas. Canister vacuums are often favored for their quiet operation, versatility, and ability to function as dust extractors—making them ideal for both residential and light industrial applications where precision and flexibility are required.

Upright Vacuum Cleaner

Upright vacuum cleaners are renowned for their vertical design, robust suction, and effectiveness on carpets and large floor areas. They typically feature wide cleaning paths, rotating brush rolls for deep-pile carpet cleaning, and bag or bagless dust containment. Many upright models include flexible hoses and attachments for above-floor cleaning and hard-to-reach spots. Upright vacuums are widely used in homes, hotels, offices, and retail spaces for their efficiency and ease of use.

Handheld Vacuum Cleaner

Handheld vacuum cleaners are compact, lightweight appliances designed for quick cleanups and spot cleaning. Their portability makes them ideal for removing dust and debris from upholstery, stairs, vehicle interiors, and tight corners. Equipped with powerful motors and rotating bristles, handheld vacuums excel at lifting embedded dirt. They are a popular, budget-friendly choice for homeowners, car owners, and anyone needing a convenient supplemental cleaning tool.

Automatic Vacuum Cleaner

Automatic or robotic vacuum cleaners are self-operating devices that use sensors, mapping technology, and programmable schedules to clean floors with minimal human intervention. Users set their preferences—such as intensity, timing, and cleaning zones—on an onboard console or via a mobile app. Advanced models navigate around obstacles, avoid stairs, and automatically return to charging stations. Robotic vacuums are increasingly used in smart homes, offices, and light commercial spaces for daily maintenance and convenience. For industrial facilities, robotic vacuums are emerging as a way to automate routine cleaning and reduce labor costs.

Specialty vacuum cleaners are engineered for highly specific or hazardous environments, including the following types:

Explosion-Proof Vacuum

Explosion-proof vacuums are critical for environments where flammable dust, vapors, or combustible materials are present. These vacuums are built with non-sparking materials, grounded components, and sealed motors to prevent ignition sources—ensuring compliance with NFPA and OSHA standards. Applications include chemical plants, grain silos, powder coating facilities, aerospace manufacturing, and any setting with ATEX Zone 22 or Class II Division 2 requirements. Selecting the proper explosion-proof vacuum can prevent catastrophic accidents and ensure worker safety.

HEPA Vacuum

HEPA vacuums are designed to deliver the highest standard of air purity by utilizing High-Efficiency Particulate Air (HEPA) filters. These filters trap 99.97% of particles as small as 0.3 microns, including allergens, dust mites, mold spores, and fine industrial particulates. For optimal performance, many manufacturers recommend multi-stage filtration systems combining HEPA filters with pre-filters and carbon layers. HEPA vacuums are essential in healthcare, laboratories, electronics manufacturing, clean rooms, and any industry where ultra-clean environments are mandatory. They are also crucial for lead dust abatement, mold remediation, and asbestos removal.

ULPA Vacuum

ULPA (Ultra-Low Penetration Air) vacuums take air filtration to the next level, capturing 99.999% of particles down to 0.12 microns. These are essential for semiconductor manufacturing, pharmaceutical clean rooms, and other applications demanding the highest level of particulate control.

- Looking for a vacuum that meets strict HEPA or explosion-proof standards?

- Need guidance on vacuum types suited for your facility or business?

- Wondering which vacuum cleaner is best for heavy-duty dust collection or hazardous material cleanup?

Equipment Components

Industrial vacuum cleaners are composed of several core components, each tailored to the vacuum’s intended application and operational demands. Key elements include:

- Motors: High-efficiency electric or pneumatic motors drive airflow and suction. Variable-speed motors are available for precise control in sensitive environments.

- Switches and Controls: User-friendly switches, programmable timers, remote controls, and safety interlocks enhance ease of use and operational safety.

- Filters: Multi-stage filters (pre-filters, HEPA/ULPA, cyclonic separators) trap large and micro-scale particulates, ensuring high air quality and regulatory compliance.

- Housing: Durable stainless steel, impact-resistant plastics, or non-sparking alloys provide robust protection and compliance with safety standards.

- Hoses and Attachments: Industrial-grade hoses, nozzles, wands, floor tools, crevice tools, and specialty accessories increase versatility and reach.

- Collection Chambers: Large-capacity tanks or bags facilitate extended operation between disposals and support efficient waste management. Some models feature tilting or lift-off collection bins for easy emptying.

- Safety Features: Non-sparking materials, grounded components, and explosion-proof construction for hazardous environments.

- Wheels and Casters: Heavy-duty wheels or casters improve mobility, especially in large or multi-level facilities.

Filter selection is especially critical. Mechanical pre-filters and cyclonic separators capture large debris and protect primary filters, extending lifespan and performance. Nylon filters manage foamy liquids, while HEPA and ULPA filters are necessary for fine dust, allergens, and hazardous materials. Advanced filtration not only maximizes cleaning efficiency but also protects workers from airborne contaminants. Proper filter maintenance and timely replacement are crucial for sustained vacuum performance and regulatory compliance.

- Which vacuum components are most important for your application?

- How do multi-stage filters improve air quality and reduce maintenance?

- Looking for durable vacuum cleaner parts or replacement filters?

Benefits

Investing in the right vacuum cleaner—whether industrial, commercial, or residential—yields a multitude of benefits:

- Enhanced Health & Safety: By capturing dust, allergens, and hazardous particles, vacuums protect workers, occupants, and sensitive equipment from harmful exposure and contamination. This is particularly vital in industries handling toxic or combustible materials.

- Regulatory Compliance: Industrial vacuum cleaners help businesses comply with OSHA, EPA, NFPA, and ISO standards for workplace safety, combustible dust management, and environmental protection.

- Productivity & Efficiency: Efficient vacuum systems reduce downtime, minimize manual labor, and streamline cleaning processes, enabling staff to focus on core tasks and improving overall productivity.

- Cost Savings: Advanced vacuums support material reclamation, reduce waste disposal costs, and extend the lifespan of machinery by preventing dust buildup and equipment wear. Energy-efficient models also lower utility expenses.

- Versatility: With configurations for dry, wet, hazardous, or fine particulate collection, vacuums can be tailored to virtually any environment or cleaning challenge.

- Improved Air Quality: Effective particulate removal results in cleaner, healthier indoor air, reducing employee sick days and boosting well-being.

- User Convenience: Modern vacuums offer ergonomic designs, intuitive controls, and low-maintenance operation, making them accessible for workers of all skill levels.

- Environmental Stewardship: By reducing airborne pollutants and supporting responsible waste management, industrial vacuums help organizations meet sustainability goals and green building certifications.

Whether you’re searching for a vacuum solution for a high-traffic warehouse, a sensitive laboratory, a food processing plant, or a busy hotel, today’s industrial vacuums can be customized to address your unique needs and business objectives. Investing in a high-performance vacuum system also demonstrates your commitment to employee safety and environmental responsibility.

- Want to learn more about the ROI of industrial vacuum cleaners?

- Looking for ways to improve air quality and reduce workplace hazards?

Design and Customization

Industrial vacuum cleaner design is highly customizable to meet the exacting requirements of different industries, applications, and facilities. Manufacturers consider factors such as the type and quantity of material to be collected, the environment’s safety requirements, and operator preferences to deliver optimal solutions. Custom-engineered vacuum systems can include explosion-proof features, specialty filters, anti-static hoses, and IoT-enabled monitoring for predictive maintenance.

The design process begins by identifying the primary debris type—whether it’s fine dust, coarse particles, hazardous chemicals, wet materials, or a combination. For fine dust (such as silica or pharmaceutical powders), vacuums are engineered with expansive filter surfaces and high-efficiency filtration instead of sheer suction power. For metal dust or heavy debris, both high airflow and robust filtration are crucial. Specialty vacuums may be required for flammable, corrosive, or sensitive materials, with features such as anti-static hoses, sealed motors, and explosion-proof construction.

Other customizable components include:

- Hose length and diameter: Balance between reach and suction efficiency.

- Filter type and configuration: HEPA, ULPA, carbon, or hybrid systems for targeted particle capture.

- Motor power and energy efficiency: Tailored to facility size, debris load, and power availability.

- Portability: Options for stationary, wheeled, backpack, or central system configurations.

- Disposal mechanisms: Tilting chassis, quick-release tanks, drainage hoses, and sealed waste bags for safe, ergonomic waste management.

- Automation: Programmable cleaning cycles, integration with facility management systems, and IoT-enabled monitoring for predictive maintenance.

- Noise reduction: Insulated housings and low-decibel motors for use in sound-sensitive environments, such as hospitals or schools.

Partnering with an experienced supplier ensures your vacuum system is expertly matched to your cleaning needs, regulatory requirements, and operational priorities. Many manufacturers offer free consultation services, on-site evaluations, and custom engineering to create the ideal vacuum solution for your business.

- Do you need a custom vacuum for hazardous dust or wet material?

- Curious about energy-efficient or smart vacuum solutions for your facility?

- Want to schedule a vacuum needs assessment or request a custom quote?

Safety and Compliance Standards

Safety and compliance are critical considerations when selecting an industrial vacuum cleaner. Regulatory requirements vary by industry, application, and geographic location. For example, workplaces exposed to combustible dust must use OSHA-approved, explosion-proof vacuums to mitigate fire and explosion risks. Facilities focused on allergen control should seek equipment bearing the ASP:03:01 Certification Standard—indicating the vacuum is “allergy and asthma friendly” and ANSI-accredited. In food and pharmaceutical processing, vacuums must meet FDA and GMP guidelines for hygiene and contamination control.

Key standards bodies include:

- ANSI (American National Standards Institute): Sets performance and safety benchmarks for electrical and filtration systems.

- ASTM (American Society for Testing and Materials): Provides testing protocols and construction guidelines.

- UL (Underwriters Laboratories): Certifies electrical safety and explosion-proof designs.

- OSHA (Occupational Safety and Health Administration): Mandates use of certified equipment in hazardous environments.

- NFPA (National Fire Protection Association): Specifies requirements for dust collection, explosion prevention, and facility safety.

- ATEX (Atmosphères Explosibles): Sets equipment standards for explosive atmospheres, especially in Europe.

- ISO (International Organization for Standardization): Offers global standards for quality management and environmental controls.

For personalized compliance solutions, always consult with your supplier or a certified industrial hygienist. Regular employee training on safe vacuum operation and filter replacement is also recommended to maintain compliance and workplace safety.

- Which compliance standards apply to your facility?

- Looking for a list of OSHA-approved, explosion-proof vacuum manufacturers?

- Need help understanding ATEX or NFPA requirements for your vacuum system?

Things to Consider

Choosing the right industrial or commercial vacuum cleaner requires careful consideration and expert guidance. Collaborating with a professional supplier ensures you receive a solution tailored to your unique cleaning requirements, safety standards, and operational constraints. To streamline your search, we’ve assembled a list of top industry leaders, complete with detailed profiles and product specifications. Scroll to the middle of this page to explore their offerings.

When evaluating vacuum suppliers and solutions, keep the following decision factors in mind:

- Application suitability: Does the vacuum meet your specific debris, environment, and safety needs?

- Performance metrics: Consider suction power, airflow (CFM), filtration efficiency, noise level, and capacity.

- Compliance and certifications: Are all relevant OSHA, NFPA, UL, ATEX, and ISO standards met?

- Support and warranty: Assess post-installation service, replacement part availability, and warranty coverage.

- Total cost of ownership: Factor in purchase price, consumables, maintenance, and potential energy savings.

- User experience: Evaluate ease of use, ergonomics, and training requirements for operators.

- Scalability: Can the vacuum system be expanded or modified as your facility grows?

- Energy efficiency: Does the vacuum offer variable speed controls or other energy-saving features?

- Brand reputation: Research manufacturer reviews, customer testimonials, and case studies.

Once you’ve identified several promising suppliers, compile a detailed list of your requirements, and reach out for quotes and product recommendations. Compare customer service quality, after-sales support, and responsiveness before making your decision. A successful vacuum purchase is not just about product features—it’s about the dedication and reliability of your supplier.

- Ready to request quotes from leading industrial vacuum manufacturers?

- Need help comparing features and benefits before your purchase?

- Want to read customer reviews of top-rated industrial vacuum cleaners?

- Interested in learning about leasing or financing options for commercial vacuum systems?

Remember, investing in the right vacuum cleaning solution is crucial for workplace safety, air quality, and operational efficiency. Make your selection with confidence by consulting with industry experts, reviewing compliance standards, and prioritizing both performance and long-term value. Best of luck with your search!

What industries commonly use industrial vacuum cleaners?

Industrial vacuum cleaners are used in woodworking, metalworking, manufacturing, electronics production, pharmaceuticals, food processing, building maintenance, healthcare, cleanrooms, pollution control, the ceramic industry, and hazardous waste management.

How do industrial vacuum cleaners improve workplace safety?

Industrial vacuum cleaners help remove hazardous dust, toxic particulates, and combustible debris, minimizing air contamination and reducing the risk of workplace accidents, regulatory violations, and health hazards.

What are the main types of industrial vacuum cleaners?

Common types include continuous duty vacuums, auto vacuums, central vacuum systems, portable vacuums, wet/dry vacuums, canister vacuums, upright vacuums, handheld vacuums, automatic/robotic vacuums, explosion-proof vacuums, HEPA vacuums, and ULPA vacuums.

What standards and certifications should industrial vacuum cleaners meet?

Key standards include OSHA, NFPA, UL, ANSI, ASTM, ATEX, ISO, and FDA/GMP for hygiene. Compliance depends on the industry and environment, such as using explosion-proof vacuums in combustible dust areas or HEPA filters in cleanrooms and healthcare.

What components are essential in industrial vacuum cleaners?

Key components include high-efficiency motors, multi-stage or HEPA/ULPA filters, durable housing, industrial hoses and attachments, large collection chambers, safety features for hazardous environments, wheels/casters, and user-friendly controls.

How do HEPA and ULPA filters differ in vacuum cleaners?

HEPA filters capture 99.97% of particles down to 0.3 microns, making them suitable for allergen and fine particulate removal. ULPA filters provide higher filtration, capturing 99.999% of particles as small as 0.12 microns, essential for cleanrooms and critical environments.

What should be considered when choosing an industrial vacuum cleaner?

Consider application suitability, suction power, airflow, filtration efficiency, noise level, capacity, compliance, support and warranty, total cost of ownership, user experience, scalability, energy efficiency, and manufacturer reputation.

How does a vacuum cleaner work to remove dust and debris?

A vacuum cleaner generates a pressure differential using one or more fans, drawing air and contaminants inside the machine. The air passes through filters or separators that trap dust and debris before releasing clean air back into the environment.

Air Compressors

Air Compressors  Air Filters

Air Filters Air Pollution Control

Air Pollution Control Blowers

Blowers Dust Collectors

Dust Collectors Industrial Vacuum Cleaning Equipment

Industrial Vacuum Cleaning Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services