Stationary vacuum systems may serve a wide variety of applications, including spill cleanup (including explosive dust spills), material recovery, plant cleanup, batching, vacuum conveying, continuous discharging, pressure loading and unloading, pneumatic conveying and industrial vacuuming. Read More…

As a leader in the vacuum cleaner manufacturing industry, Multi-Vac offers vacuums for a variety of applications. Products include central industrial vacuums, portable vacuum cleaners and more.

Delfin Industrial Vacuums is an innovative leader in the vacuum cleaners industry. We focus on continually improving our products and our services, so you are only ever getting the best from us. Our team is dedicated to finding the right industrial vacuum system for your company’s specific needs. Delfin is an ISO 9001 certified company. We offer our customers unrivaled customer service and...

We aim to achieve measurable cost savings for you while producing a cleaner and safer work environment in your workplace. We meet your needs for cleaning or maintaining, recycling, non-destructively excavating, or improving air quality.

At Mark C. Pope Associates, we take pride in offering advanced vacuum cleaning solutions tailored to meet the rigorous demands of industrial and commercial environments. With decades of experience in the field, we have built a reputation for delivering high-performance vacuum systems that stand up to heavy-duty use while ensuring efficiency, safety, and cleanliness in every application.

More Stationary Vacuum System Manufacturers

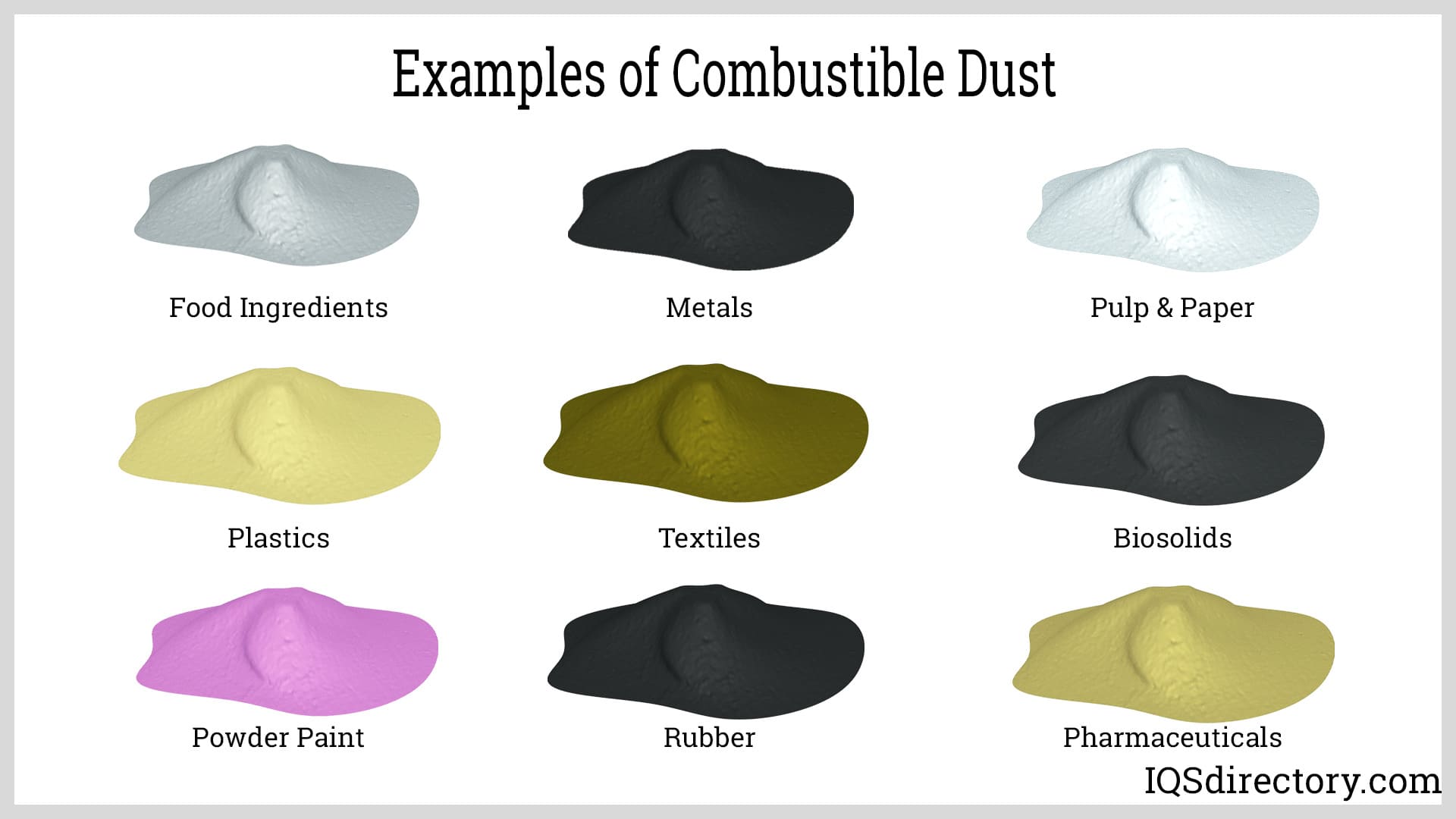

The type of system a stationary vacuum manufacturer will build for you depends on your application specifications, most notably the materials you need it to gather. Some of the materials that stationary vacuum systems most commonly consume are dusts, such as sawdust, explosive dust and hazardous dust like asbestos dust. They also deal with materials like metal waste (ex. iron chips), blasting media, plastic resin, organic fibers, insulation, gravel and free flowing media like cement slurries.

Manufacturers design stationary vacuum systems with a wide variety of features, per your requirements. Many, for example, come equipped with hoppers, which serve as the place gathered materials can be collected and then sent on for reuse or another application. To reuse or recycle said materials, these vacuum systems often also feature components like system separators and cleaning tools. Other vacuum systems feature load cells that weigh the materials they have collected. Still others feature belts for conveying materials through a central vacuum system. Some even come with a special high temperature resistant construction. In addition, many feature inlets where users may attach nozzles and hoses for focuses cleaning.

Stationary vacuum systems offer their users a wide variety of advantages. First, they quite versatile. Second, they take several cleaning tasks and roll them into one. Third, they are less labor-intensive and cumbersome than portable vacuum systems. In addition, they are powerful; they’re usually available powers up to 30 HP. Also, they are the perfect way to meet EPA requirements. Finally, because they can run 24/7 and require little to no operator assistance, they are incredibly efficient. They are an investment, but in the long run, they will save you quite a bit of money.

Air Compressors

Air Compressors  Air Filters

Air Filters Air Pollution Control

Air Pollution Control Blowers

Blowers Dust Collectors

Dust Collectors Industrial Vacuum Cleaning Equipment

Industrial Vacuum Cleaning Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services